Home

Menu

Base Unit

Lift

duct Thrust

Duct Motor

Mounts Front

Cabin

Centre Cabin Air Duct Cover Skirt R/C Installation

The Skirt

The Patterns

The skirt patterns were downloaded from Mark's site but they need expanding

before they can be used.

I used Corel Draw's real world dimensions to expand the patterns to the correct

size for the model.

Please note the following update on the patterns- Jan 2004)

Users have reported problems with the dimensions

when printed out from the PDF file. I have found that the PDF file has lost

the overlap I had originally set up to enable the printouts to be made into

the correct patterns. I cannot cure this problem so have recreated the patterns

in a different format before passing to the PDF creator.

The following photos show the sequence to joining

the patterns. P1 is the same except there are four pieces instead of two.

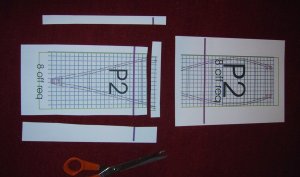

Printout

of pattern P2 |

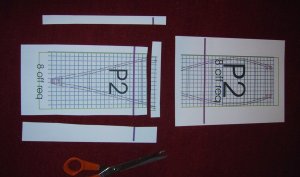

Trim some material off

the sides and top of the lower part |

|

|

|

|

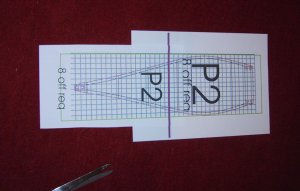

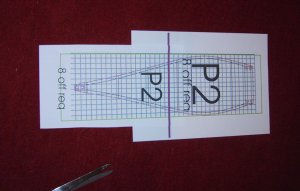

Lay

the lower part over the top part and align the thick colour bars

and the border edging. Glue the parts once aligned, I used sellotape. |

Trim off the excess material to give the pattern |

|

|

Please also note that as the patterns are blown

up from Marks originals on his site the grid of 10mm is not consistent across

the pattern. I have maintained the aspect ratio of the originals. This means

that the patterns are slightly undersize giving a length of 380mm instead of

387mm. I assume this is due to the graphic compression used on the originals.

This does not prevent the skirt from working but the centre section which Mark

sizes as 600 x 387m should be checked by measurement on your machine after

temporary fitting of the front and rear skirt sections. If you want to make

the patterns as close to Marks as possible then add 3mm to each side and 7mm

to the top and bottom of each pattern when cutting. These additions should be

corrected for your own patterns by measurement before trimming. The following

sizes should help.

P1= 312mm wide x 387mm long P2=

113mm wide x 387mm long

P3a= 136mm wide x 387mm long P3b=

136mm wide x 387m long

The Full size patterns can be printed from the following PDf file.

Full size skirt patterns(download PDF file) (310Kb)

(The

text and above photos are included in the PDF file for reference)

When the file is displayed, you will

need Acrobat reader, print out the pages. You will get 10x A4 pages which need

trimming and pasting together to give the patterns. Take care in matching up

the pages, the coloured borders and green cross enable this. Use the coloured

borders to identify the correct matches.

I copied enough patterns so that I could lay out all the patterns required

before cutting any skirt material. This way I could make the best use of

the material.

Skirt Material

The material I used is a rubberised nylon material used for tent making.

It is light and very strong, the skirt is still going without holes after 12

months use on land and water. No water has ever entered the interior of the

skirt chamber during this time.

Gluing the skirt sections

Construction of the skirt is achieved by gluing the edge of each pattern

together using approx 5mm of material at the edges. I cut a Fablon template

to match the curved edge of the templates and use this as a guide to prevent

the glue from spreading out across the material when the two edges are pressed

together. The skirt was assembled as four separate corner sections. The seams

were then machine stitched through the glued area. If this is done while the

glue is still tacky then a water proof stitch will be made. The front and rear

centres were then added and stitched followed by the long side sections. Take

care with these to prevent a twist in the skirt, it is easily done. Use a strong

thread and fine stitch on the machine when sewing.

Skirt mounting

Original baton mounted skirt with baton removed |

Front end of skirt with baton removed |

Baton and clips that hold top edge of skirt |

Sealed front flap valve can be seen |

Corner mounting |

Front-- adjusted position of skirt mount can be seen

|

The skirt was originally mounted using a bolted wood clamp method, this was

later changed to self adhesive tape without any problems. The skirt can be removed

and replaced after inspection without changing the tape.

To fit the skirt place the double sided tape all round the outer edge of

the model then start attaching the skirt by fixing the front straight edge first,

then the first corner on one side and then the other corner. Do not attach any

of the side material yet. Attach the rear straight edge and corners just as

the front. Lastly attach the side edges before attaching the lower skirt edge

using waterproof tape. Again attach the front and back sections first followed

by the sides. Any excess, there should be very little, should be gathered in

at the corners. I then fitted a door stop rubber foot to each corner to prevent

damage to the model when settling on hard ground but also to add strength to

the skirt attachment at the corners as this is where it all comes undone first.

I found a problem when blowing up the skirt for the first time in that the

skirt at the front and back of the model did not correctly match the floor contact

of the sides. Mark's dimensions for the outer deck edge at the sides do not

match the dimensions for the front and rear equivalent deck edges. The skirt

lower fitting at the front and back needs to be moved in towards the center

of the model by 30mm to correct this problem. This gives an even skirt shape

around the model and prevents the air loss I had when first running up the model.

Air filled skirt viewed via glass panel -rear end |

Air filled skirt viewed via glass panel -front end |